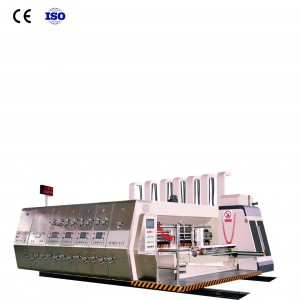

Carton tshuab luam ntawv

Lub tshuab no tawm hauv CE raws li tus qauv, nws yog standardized, generalization, humanization. Txiv neej-tshuab sib xyaw ua ke, raws li kev tsim cov pwm ncaj qha hauv kev sib chwv, teeb tsa, hloov kho, ua tiav, hloov pauv, nco, nws yog kev lag luam tshuab.

Ob chav kaw lus ntawm lub vijtsam kov thiab lub khawm hluav taws xob tswj, ua kom lub luag haujlwm ntawm kev txawj ntse xoom rov qab, nco rov qab pib dua thiab tsis siv neeg txiav txim tsim; tuaj yeem xaiv qhov kev pabcuam chaw taws teeb.

Screen, PLC .transformer, servo lub cev muaj zog siv SIEMENS, Bosch, Yaskawa.

Cov iav kis tau tus mob yog ua los ntawm high-zoo alloy steel 20CrMnTi, lub Rockwell hardness ntawm lub zog yuav tau mus rau HRC58-62 5. Tag nrho cov menyuam thiab qag yog ua nyob rau hauv ib tug txiav tshuab, xyuas kom meej thickness accordant .steady thaum high speed workK; Tom qab ntau qhov kev sim los daws qhov kev ntxhov siab zoo, los ntawm kev sib tsoo cov txheej txheem ntawm kev tiv thaiv thaum machining.

Siv qhov sib koom nrog cov tsis yog keypiece thiaj li yuav txo tau qhov sib txawv ntawm kev sib txuas thiab lub sij hawm ntev kev tso npe raug.

Tsav los ntawm cov tsev kawm ntawv hauv cov nag splashed tiv thaiv cov cuab yeej; lubrication tshuab txiav, nruab avert leaking roj sector.

Muaj peev xwm xaiv chambered hniav system, IR ziab, UV kua roj vanish.

Pub muaj nuj nqi

■ Servo tswj cov hlau lead, tau teb rau ceevtprecision thiab positioning system stability thiab ntev siv lub neej, uas tshuab mus ntev stability.

■ Nrog lub cam hloov lub cxxnplex machinery ntawm lub cams tswj, pub qag thiab lub cev muaj zog qag siv synchronous tsav siv txoj hlua txuas, tshem tawm qhov sib txawv thaum lub log feeder ua haujlwm, zoo txhim kho cov khoom noj kom raug, avert ntawv incline rau sab laug thiab sab xis.

■ Nqus nqus tsev vacuum, tuaj yeem xaiv cov khoom noj txuas ntxiv thiab hla cov khoom noj; nruab lub tshuab nqus tsev vacuum, thiab tuaj yeem kho kiv cua.

■ Cov qauv tshwj xeeb ib nrab lub log thiab hloov ceev. cia feeder log nto fray accord; hloov resinic log yooj yim thiab sai, txo lub sij hawm kho, tuaj yeem siv tshuab yooj yim thiab kev lag luam.

■ Muaj peev xwm teem caij, nres feeder v/hen ua tiav kev ua haujlwm; sab laug thiab sab xis -baffle.kack-baffie txoj hauj lwm hluav taws xob hloov kho, sab ntawm qhov zaus ntawm lawv txoj haujlwm tuaj yeem teeb tsa, ua tiav kev sib txuas ua haujlwm nrog tsis siv neeg feeder.

■ Pem hauv ntej thiab nram qab roj hmab cov menyuam rau feeder ob lub menyuam cov qauv, xyuas kom meej nyob rau hauv daim ntawvtkua nplaum rau sab nraud yog mos thiab tawv nrog ib tug zoo stretch.

Kev luam ntawv muaj nuj nqi

■ Ob chav kaw lus ntawm lub vijtsam kov thiab lub khawm hluav taws xob tswj, tuaj yeem tswj cov qib luam tawm thiab txoj haujlwm axis; luam phaj cov menyuam tuaj yeem nco thiab rov pib dua.

■ Kev ua haujlwm lub ntsej muag-phaj teeb tsa tus cwj mem rau cov menyuam thiab cov twj tso kua mis khiav lossis nres; txhua chav tsev muaj qhov hloov chaw nres xwm ceev.

■ Anilox cov menyuam txuas txuas nqa ntawm chav tsev pub khoom noj, luam ntawv phaj kis hluav taws xob kho thaum inking; print phaj roller gap hluav taws xob khotthiab tuaj yeem kho kiv cua.

■ Roj Hmab cov kua nplaum spillover system siv cov technics tshiab, tsis tsuas yog tiaj tus xim luam ntawv, tab sis kuj 60 kab luam ntawv.

■ Muaj peev xwm xaiv chambered hniav, siv cov kev teeb tsa uas tus number case faib tawm kom tag nrho, tiv thaiv tus number case spillover zoo, Ua tiav 100 kab luam ntawv yooj yim 'nce kev pab cuam lub neej ntawm cov hniav thiab anilox cov menyuam.

■ Luam theej duab theem siv electromagnetic clutch nres mechanism, vrfien teem cais tuaj yeem kaw lub iav uas tuaj yeem luam phaj txoj hauj lwm pib dua.

■ Nruab qhov hluav taws xob taw tes hloov, tuaj yeem phaj thauj khoom thiab kho sai sai .yooj yim hloov thiab dean luam phaj.

Slotting muaj nuj nqi

system ntawm kov npo thiab hluav taws xob khawm tswj, tuaj yeem ua tiav ntawm lub thawv, theem. lub axis txav.

Configuration siab ceev kho mechanism, thiab muaj peev xwm ua rau nws tus kheej-locking, xyuas kom meej lub phaj thiab cov menyuam lub sij hawm ntev precision, qeeb kev puas tsuaj rau cardboard thaum zawj.

Lub Up-groove log parcel lub zoo polyurethane .tsis txhob cardboard hardness undermine.

Kev teeb tsa synchronous yam sib koom ua ke los ntawm axis txav, cia nce thiab nqis groove log, nce thiab nqis qhov riam phaj, taw qhia log kho synchronous; Tsis siv neeg hnav-tiv taus mechanism, xyuas kom lub sij hawm ntev kom raug v/tien txav thiab tsa durability.

Groove log thiab cov menyuam, lub log thiab cov menyuam siv cov khoom siv hlau zoo, sib tsoo nto thiab tawv chrome plating; txav lawv qhov sib npaug.

Slotter riam siv cov khoom siv hlau zoo, v / idth yog 7 hli.

Tuag-cutter muaj nuj nqi

Ob chav kaw lus ntawm lub vijtsam kov thiab hluav taws xob khawm tswj, tuaj yeem tswj cov theem thiab axial ntawm chav txiav tuagtthiab nruab lub khawm kom tswj cov ntawv luam tawm thiab lub qhov rooj .setting lub ntsiab lub cev muaj zog khiav lossis nres, nrawm lossis decelerate.

Txais tos tshwj xeeb sab hauv striker them nyiaj kev npaj, thaum anvil muaj qhov hloov pauv, tuaj yeem txiav cov kab nrawm them nyiaj, xyuas kom muaj qhov sib xws ntawm kev tsim khoom, thiab ua kom lub neej ntev.

Thaum tuag cutter pib ua hauj lwm, tuag cutter cov menyuam cia li nce mus rau txoj hauj lwm, anvil cover roller nkag mus stale; anvil cover thiab tuag cutter roller nrog sib txawv speeds tsim; nruab anvil npog automated txiav kho tsevttuaj yeem kho anvil npog lub sijhawm thiab sijhawm dua.

Tuag cutter roller, anvil cover roller siv cov khoom zoo steel, Quenching ua ntej thiab muab qhov chaw txiav rau sab hauv thiab sab nraud los ntawm kev sib tsoo kev ua haujlwm thiab nyuaj chrome, txav lawv qhov sib npaug.

Txhim kho txoj cai sib txawv ntawm kev vibration.

Muaj peev xwm xaiv servo tswj ceev them nyiaj mechanism, tuaj yeem ua rau lub thawv siab.